From PS5 to Ford F-150: How a global chip shortage is ‘impacting everything’

Cristiano Amon, incoming CEO of chipmaker Qualcomm, warns in an interview with CNET that the shortage may not end until late 2021.

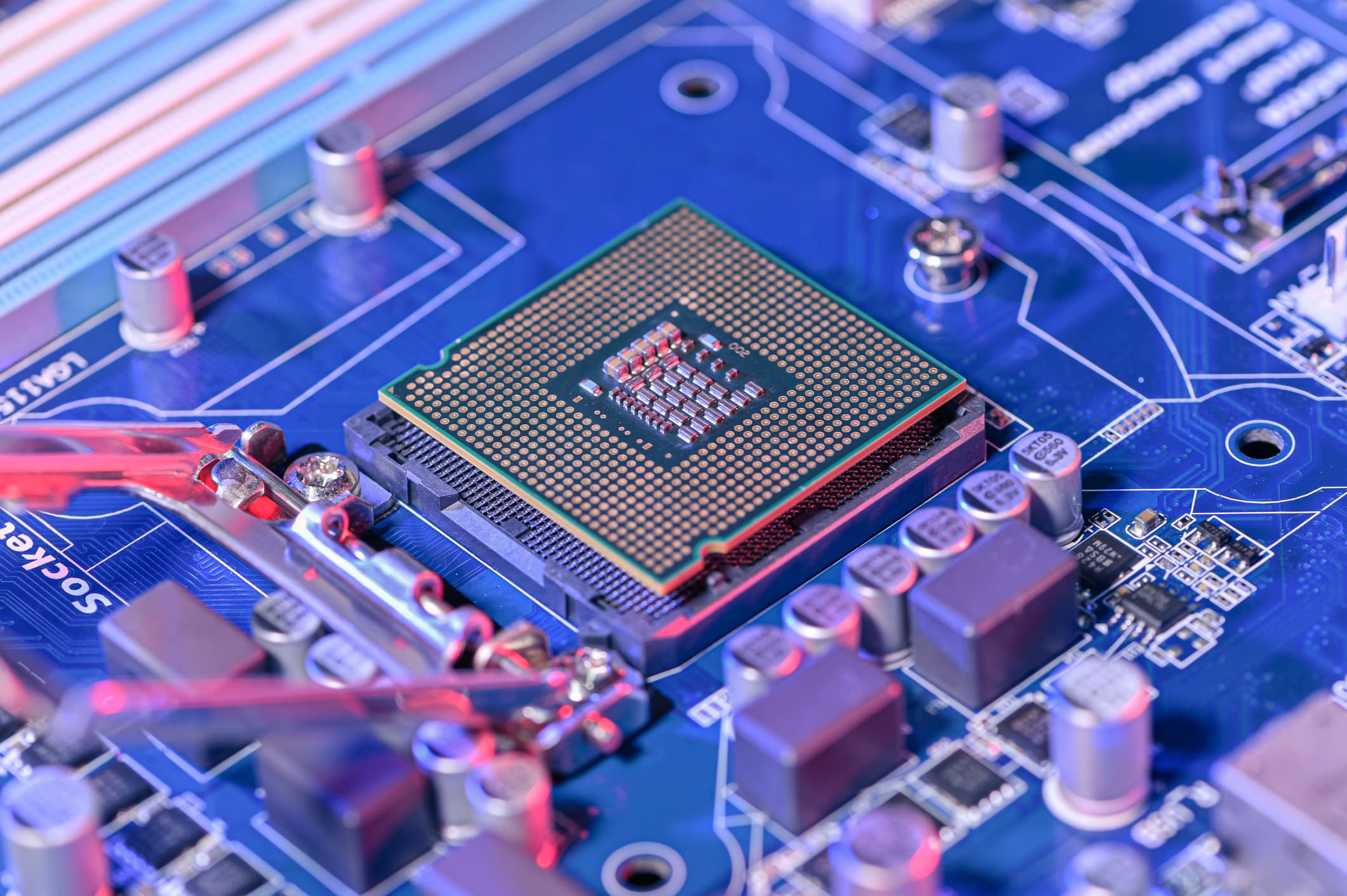

The biggest news in the automotive industry right now isn’t new electric vehicles or Tesla CEO Elon Musk’s latest comments. It’s a major semiconductor shortage that’s hurting automakers across the globe. Because Ford, General Motors, Toyota and others can’t get certain electronic components they need, they’re cutting production on vehicles like the Ford F-150.

And it’s not just cars. There also are shortages in chips for Sony Playstation 5 and Microsoft Xbox Series X consoles, and people have been camping out — during a pandemic — to buy Nvidia’s graphics processors. Even Qualcomm, the world’s biggest mobile chipmaker, can’t get enough processors to meet the demands of its handset customers.

It’s this situation — more than competition or a lukewarm consumer reception to 5G — that worries Qualcomm’s incoming CEO, Cristiano Amon. The 50-year-old Brazilian has been at Qualcomm since 1995 and became president in 2018. He’ll become only the fourth CEO in the 36-year-old company’s history when he takes over the helm from Steve Mollenkopf in June. With that role will come pressure to not only keep Qualcomm as the leader in mobile chips, but also expand the company into new markets with its 5G connectivity.

“If you asked me, ‘what keeps me up at night?’ right now [it] is this supply chain crisis we’re having in the semiconductor industry,” Amon said in a wide-ranging interview with CNET. While it’s happening because there’s high demand for tech products, he said, “it is causing a lot of stress as the supply chain was not prepared to deal with the growth.” And the shortages likely will continue until late 2021, Amon added.

When the novel coronavirus pandemic hit last year, people stayed at home and stopped shopping. Factories closed, and companies pared back orders. But then demand roared back faster than anyone expected, especially for devices to help people work and attend classes from home. Apple couldn’t meet the demand for its iPhones, computers and webcams sold out virtually everywhere, and schools couldn’t get devices they needed for at-home instruction.

Amon described it as a “V-shaped recovery:” a huge dropoff in purchases, followed by a rapid return of demand. But component manufacturers couldn’t keep up with the surge. Automakers’ just-in-time manufacturing strategy, which has long benefited them, backfired. When the pandemic hit, they canceled orders, only to find the supply wasn’t available when demand returned.

“As more and more devices have gotten digital over the years — cars are the best example — the amount of semiconductor demand has grown to the point that people are battling over capacity that’s available,” Technalysis Research analyst Bob O’Donnell said.

At the same time, Huawei’s decline in the phone market has impacted the technology industry. Last summer, the Chinese company became the world’s biggest phone maker for a quarter, the first time in nearly a decade that Apple or Samsung hadn’t held the title. But US sanctions against Huawei are hurting its ability to sell devices, opening an opportunity for other Android handset makers to woo its customers. That creates even more demand for processors from companies like Qualcomm, but the supply chain wasn’t prepared for it, Amon said.

“We have an incredible crisis in the supply chain.”Cristiano Amon, Qualcomm’s president and incoming CEO,”So you add all of this together, we have an incredible crisis in the supply chain,” Amon said. The shortage is “impacting everything, and of course [is] impacting phones.”

On building chips

If there’s a shortage, why not build more factories to produce chips? The Biden administration last week said it would review critical supply chains, including semiconductors, over the next 100 days, as well as allocate $37 billion to boost chip manufacturing in the US.

“Recently, we’ve seen how a shortage of computer chips … has caused delays in production of automobiles that has resulted in reduced hours for American workers, a 21st-century horseshoe nail,” President Joe Biden said last week. “We need to make sure these supply chains are secure and reliable.”

Here’s the rub: It costs billions of dollars to construct new fabs, and they can’t go up overnight. Most advanced processors are built overseas.

Most chipmakers like Qualcomm don’t actually build their own semiconductors. They design their processors and then hire companies like Samsung and Taiwan Semiconductor Manufacturing Company, better known as TSMC, to actually manufacture them in factories called fabs.

Source: Shara Tibken

熱門頭條新聞

- In conversation with ‘Ultraman Rising’ director Shannon Tindle: Insights on storytelling, innovation, and collaboration in animation

- Breaking Free: Disney Declares Independence from the Apple App Store

- Warner Bros Discovery confirms Max launch in seven Asian markets

- A look at the winners of the 72nd San Sebastian International Film Festival

- Talpa Studios and Hasbro Entertainment showcased Trivial Pursuit at MIPCOM 2024

- NARAKA: BLADEPOINT Invites You to Dance with the Spirits

- Curve Games Signs Publishing Agreement with Patattie Games for Upcoming Title Wax Heads

- DUBAI STUDIOS SIGNS PARTNERSHIP WITH INTERNATIONAL ACADEMY OF TELEVISION ARTS & SCIENCES